Concept

Added value, exclusivity and distinctiveness are Artidoro supporting concepts for the customization of each wristwatch.

We are driven by our passion for watch making, inspired by the artisan tradition and the Italian taste for beauty and guided by the individual Customer’s request of exclusivity.

Creativity and craftsmanship are our own fundamentals because of our knowledge and historical tradition.

Creativity and craftsmanship are our own fundamentals because of our knowledge and historical tradition.

Mechmod Collection

With this Collection our company intends to launch mechanical improvements that not only change the image of the customized watch but also its mechanism or the way the time is read in a unique and exclusive manner, in terms of aesthetics and functionality.

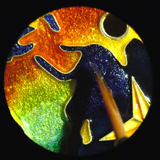

Enamel Collection

Champlevé is an enameling technique in the decorative arts in which hollows or grooves are made into the surface of a metal object and filled with vitreous enamel.

The piece is then fired until the enamel fuses, and when cooled, the surface of the object is polished. The untouched sections of the original surface remain visible as a frame for the enamel designs.The technique has been used since ancient times and although it is no longer among the most commonly used enameling techniques, we still use it to manufacture custom designed enamel watch dials.

Making one single enamel dial is a challenging task, which can entail over a hundred hours and only a very small handful of craftsmen have the knowledge required.

Enamel is incredibly strong and its color does not fade in time. This is why historical pieces remain as vivid as when they were first made.

Keeping the Art Alive: The Enamelling Process

There is something rather mystical about the Art of Enamel. Perhaps it is due to its ancient origins or because it is one of the best kept secrets of watch making.

Today it is hard to believe that the art of dial enameling was so close to extinction. Fortunately, artists have managed to revive the craft together with the help of brands of watches, such as Patek Philippe and Vacheron Constantin, who believe in keeping these century-old crafts alive. They were not wrong! Today, certain enamel timepieces are the most sought-after collector’s items and many new customers are discovering the beauty of this miniature art for the very first time. However, what is truly beautiful about the art of enamel is that the process is as fascinating as the result.

Enamel is a type of glass powder that is applied onto a metal support and heated until the two fuse together. Its properties include a mixture of silica, a sand-like material, and a variety of other substances such as sodium, potassium carbonate and borax, which are prepared according to traditional recipes.

The drawing of the subject is the first step in the production process of an enamel dial.

Today it is hard to believe that the art of dial enameling was so close to extinction. Fortunately, artists have managed to revive the craft together with the help of brands of watches, such as Patek Philippe and Vacheron Constantin, who believe in keeping these century-old crafts alive. They were not wrong! Today, certain enamel timepieces are the most sought-after collector’s items and many new customers are discovering the beauty of this miniature art for the very first time. However, what is truly beautiful about the art of enamel is that the process is as fascinating as the result.

Enamel is a type of glass powder that is applied onto a metal support and heated until the two fuse together. Its properties include a mixture of silica, a sand-like material, and a variety of other substances such as sodium, potassium carbonate and borax, which are prepared according to traditional recipes.

The drawing of the subject is the first step in the production process of an enamel dial.

The idea is given to an artist who elaborates the drawing.This is then transformed into a “technical drawing” to process the 18 or 22 kt gold leaf, which is engraved to create the “cells” that will then be filled with enamel and fired.

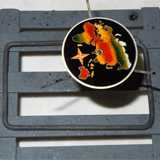

The metal base plate of the customized dial is gold. Before the enamel can be applied, any metal oxidation must be removed in an acid bath. Metals can have different reactions to heat; metal reacts to heat at over 800 degrees Centigrade.

Gold can melt and therefore, you have to be very careful to stay within the limits. Rough pieces of enamel are milled with a mortar and pestle and washed several times in distilled water so as to obtain a fine and uniform enamel powder.

The most delicate part of the whole process is then reached: the passage into the kiln,

where the powder melts at 800 degrees, thereby becoming shiny and transparent.

The process to produce an enameled dial in different colors can take up to100 hours and 10 consecutive firings in the kiln. The result can be compromised with each step, which leads to the enameller having to start the whole process again from the beginning.Polishing is the next step. The enamel is made flat, uniform and perfectly polished and the outline of the design, which consists of thin gold threads, emerges in all its beauty.